LubeCoach - Grease Lubrication Calculator app for iPhone and iPad

Developer: Advanced Machine Reliability Resources, Inc.

First release : 19 Jun 2013

App size: 4.86 Mb

LubeCoach helps managers improve lubrication practices, improve productivity and reduce maintenance cost. LubeCoach helps to create a machine-specific best practice for all types and sizes of bearings operating in any industrial environment.

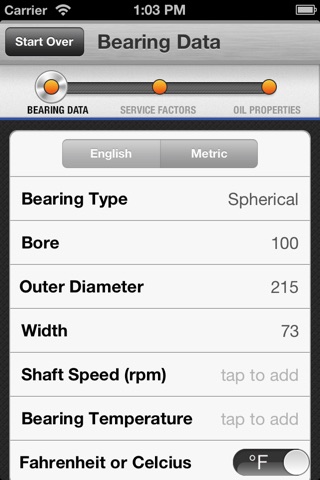

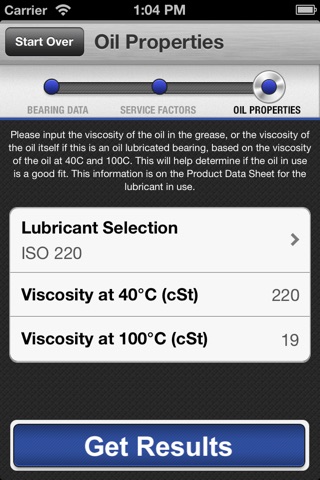

Using LubeCoach, engineers can define each bearing and the operating context, calculate the proper relubrication requirements, and optimize labor resources needed for machine lubrication. Bearings dimensions are pulled from a bearing library (or keyed in), matched with operating conditions, matched with the lubricant brand/type, and then provided with a relubrication routine.

Once the calculation is completed LubeCoach Users can capture the information in an email (or in the near future store the information in a password accessible web-database) for future use.